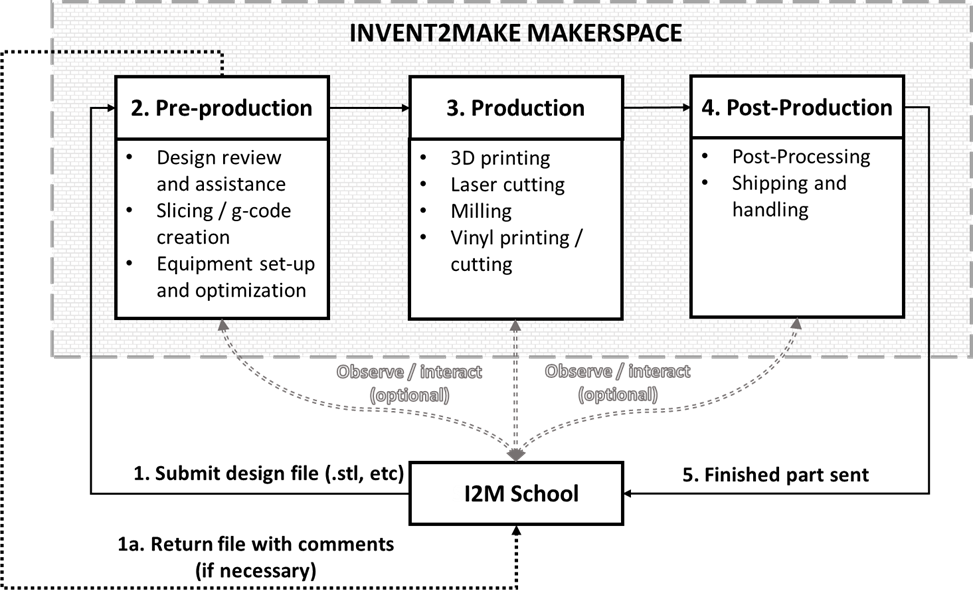

The Invent2Make Makerspace Model

Membership in the Invent2Make Program, offered by Vista AST, includes virtual access to the diverse array of digital manufacturing equipment and expert support staff of the Invent2Make Makerspace, a state-of-the-art facility housed adjacent to America Makes, the national research and development center for additive manufacturing. The I2M Makerspace provides all of the necessary tools and resources to bring students’ inventions to life, offering assistance and expertise in every step of the fabrication process:

Pre-production Services

1. Submit Design File

Using the Invent2Make online support system, student project design files are submitted to the Invent2Make Makerspace for production and return shipping. Files should be of the appropriate type for the preferred manufacturing method – these will typically be .stl files for 3D printing or milling. A support ticket is created when the files are submitted to track fulfillment of the production request.

2. Pre-production

The I2M Makerspace provides all necessary pre-production services necessary to take a student design and prepare it for production, including design review and assistance, slicing/g-code creation and equipment set-up and optimization. At each step in the pre-production process, students and educators can interact with I2M staff to understand design considerations, equipment and material alternatives and requisite computer software.

- Design Review and Assistance

Oftentimes student designs are not able to be fabricated due to design issues, ranging from floating objects to collisions to incomplete designs or unsuitable geometries. I2M staff meticulously review each design file sent to the Makerspace to identify any issues and then work closely with the educators and/or students to resolve these issues so that the design can be successfully fabricated.

- Slicing / G-Code Creation

When converting a design file to a g-code file, a file that the machine tells the machine how to build the part, there are a multitude of parameters and factors to consider to attain the desired result. For example, when using a slicing software to prepare a file for 3D printing, there are parameters such as print temperature, feed rate, infill shape and density and use of support material, among others, that need to be appropriately set for the part specifications and intended use case. I2M staff use appropriate machine-specific software to create production-ready g-code files with requisite settings and parameters to yield desired results.

- Equipment Setup & Optimization

Prior to fabrication, I2M staff setup and optimize each piece of equipment to ensure that parts are fabricated to the needs of the designers. I2M staff ensure suitable material is utilized in the production process, for example ABS vs PLS or glossy vinyl vs matte vinyl, based on project requirements. The machine with the appropriate configuration is selected based on material and production parameters – for 3D printers this could be use of a printer heated bed or larger print volume, or for mills this could be use of a mill with a rotary attachment. Machines are physically set-up to optimize results: selection of appropriate nozzle size (3D printing), laser intensity (laser cutting), bit size/shape (milling), etc.

Equipment and Production Services

Once a design file has been reviewed and accepted, it enters the production phase where an I2M Makerspace staff member fabricates the part using the desired digital manufacturing technology: 3D printing, laser cutting, CNC milling/routing or vinyl printing/cutting. Schools have the option to observe and interact with the equipment operator, and in many cases with the actual equipment itself, to understand operations and functionality of the equipment as well as view the part being fabricated. I2M staff have 24/7 access to the makerspace to ensure that production orders are turned around quickly, with a goal of one week or less. Each of the types of manufacturing technology offered by the I2M Makerspace is discussed below.

- 3D Printing

With more than 60 3D printers, the I2M Makerspace adds significant 3D printing capacity to any participating school. Common obstacles that inhibit adoption of 3D printing in the classroom is that build speeds can be slow, limiting student access, and 3D printers can be difficult to get back online once they inevitably experience some issue. Having the support of the I2M Makerspace to support some or all printing needs ensures participating educators have the resources they need to seamlessly integrate 3D printing projects into their lesson planning. The 3D printers in the I2M Makerspace feature both standard and large format build volumes and can accommodate a wide variety of filament types, including PLA, ABS, PETG, nylon, flexible and wood and metal infused.

- Laser Cutting

The I2M Makerspace features 2 Epilog Mini Laser Cutters that are capable of precisely engraving, etching and, of course, cutting a wide variety of materials, including acrylic, wood and glass. Laser cutters are costly and require suitable ventilation systems and awareness of fire risks presented while in use, and as a result this type of technology isn’t always a great fit for in-class use. The I2M Makerspace offers direct access to this exciting technology without the challenge of procuring and safely operating this equipment. The I2M laser cutters include a rotary attachment to enable cylindrical engraving/etching.

- CNC Milling

CNC mills yield three dimensional parts similar to 3D printers, however they offer a wider variety of material types and can more reliably produce certain geometries that aren’t as compatible with 3D printing. While 3D printers are restricted to polymer materials, mills can utilize woods and composites to meet a wider range of use scenarios – 3D printed parts, for example, deform at higher temperatures. Fabrication using the mills starts with the same CAD file format as in 3D printing (.stl), but utilize a subtractive manufacturing process where material is removed from the feedstock to produce the desired result. In addition to being costly, CNC mills require a higher level of operator knowledge than other types of makerspace equipment, as the operator must select the appropriate tooling for a particular job, and as such CNC mills are not a good fit for in class use in many circumstances. The I2M Makerspace removes the burden of CNC ownership and operation while facilitating adoption of this equipment in participating classrooms.

- Vinyl Printing / Cutting

The I2M Makerspace includes two Roland BN-20 Vinyl Cutter/Printers for high resolution, colorful prints and precision cuts. From stickers and decals to posters and banners to buttons and t-shirts, the BN-20’s can support almost any classroom subject, from traditional STEM subjects to the arts to entrepreneurship. Vinyl printer/cutters require constant power and internet access in addition to high ongoing maintenance costs due to expensive ink, but the I2M program provides participants direct access to this equipment without these cost impacts and logistical challenges. The BN-20’s are capable of printing on heat transfer material, which can be used to make t-shirts and sweatshirts using a heat press.

Post-Production Services

Once a student project is produced, I2M staff work expeditiously to post-process the part, if requested, and return ship the project back to the requesting school as soon as possible.

- Post-processing

Participating schools are provided with several options for post-processing depending on the type of equipment used. For 3D printing, post-processing can include removal of support material, filing and sanding, polishing, painting and assembly. Postprocessing for laser cutting can include cleaning and removal of partially cut/hanging pieces. For CNC mills postprocessing can include cleaning, sanding and painting/staining. Finally for vinyl printing/cutting, post-processing can include removal of unused material, heat pressing and button-making. These services are offered at no charge to participating schools.

- Shipping

Membership in the I2M Program includes packaging and shipping of student projects from the I2M Makerspace to the participating school. We understand that oftentimes these projects need to be produced in a timely manner to coincide with the class schedule, and so we strive for as quick of a turnaround as possible, with a goal of shipping in one week or less from the time the design file is received.